A highly compact and custom electrical enclosure on a robot end effector needed to be redesigned. The existing cover, developed by others, had several shortcomings that needed to be addressed:

The assembly of the cover and integration with the end effector went very smoothly and everything fit together as intended. Due variations of end effectors, a second cover was also designed and manufactured using the same process but with different handle and latch locations.

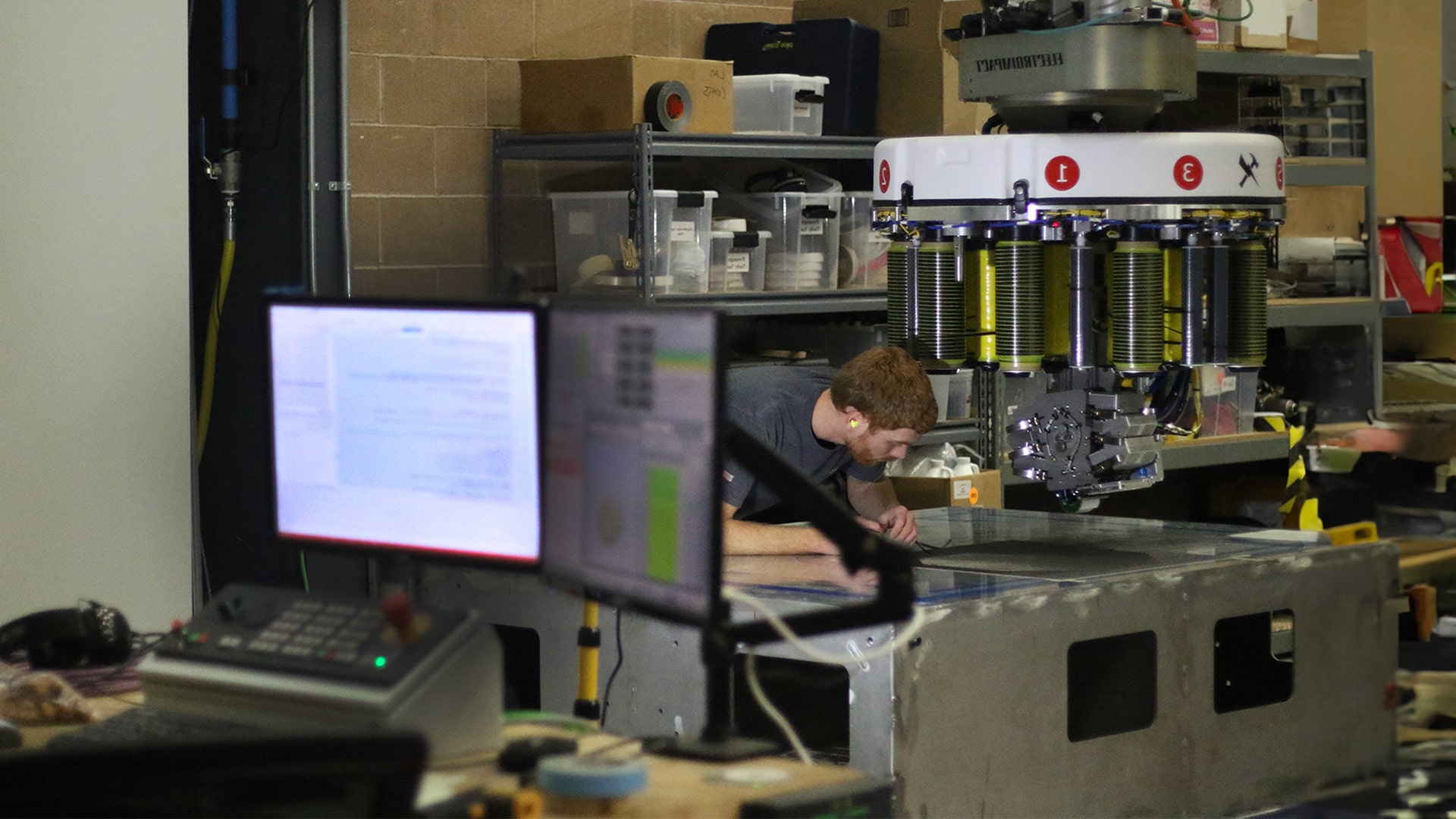

My name is Jeff Sloop and I am a mechanical engineer with over ten years of experience in design, manufacturing, and automation.

Take the first step towards optimizing your operations – request a quote today and see how we can tailor automation solutions to fit your unique needs.