The process for the manufacturing of an industrial cutting tool involved a lot of manual labor, training, and human inconsistency. It was desired to develop an automated system that could produce the cutting tools without the operator induced variables. The company also had several old robots sitting around that they wanted to repurpose for other tasks.

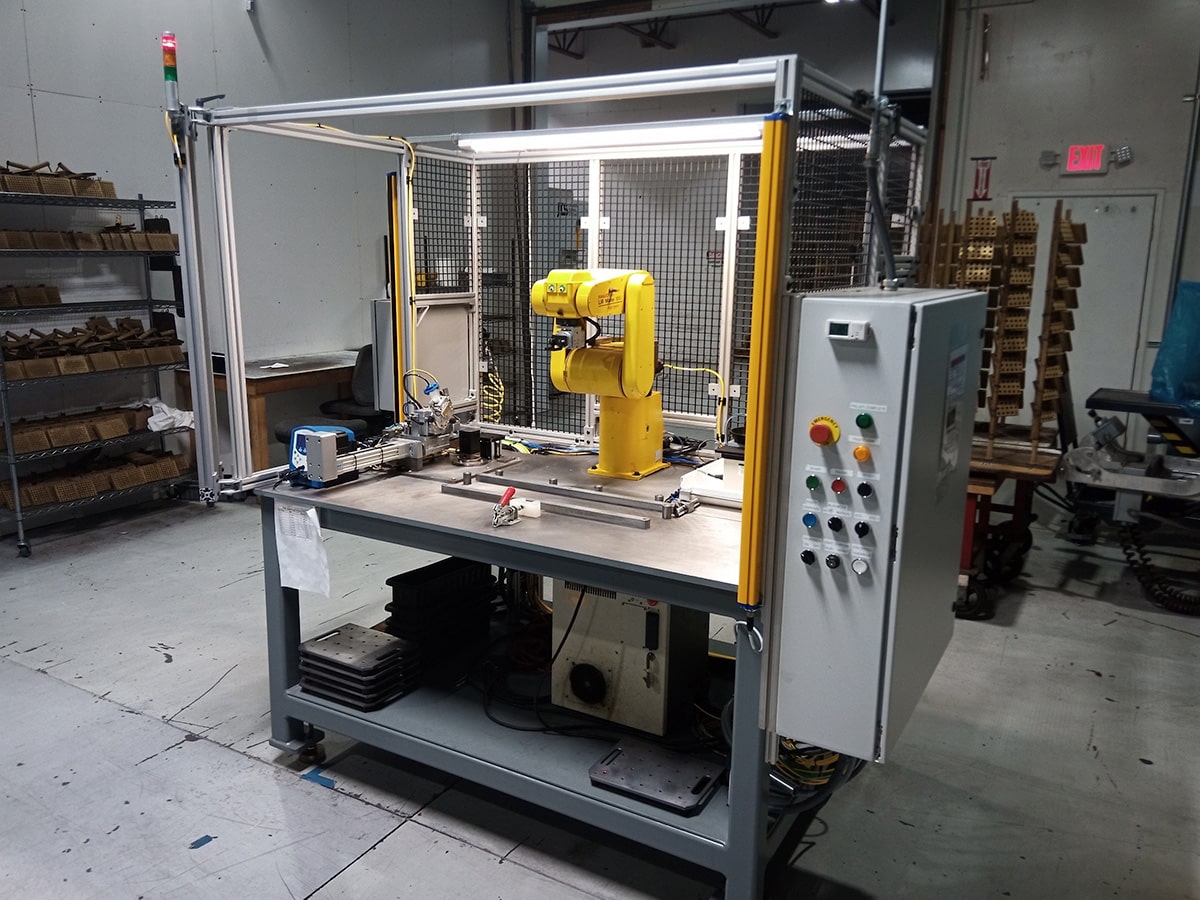

After much testing and iterating, it was decided to use an EFD dispenser to meter braze paste onto the part. This was accomplished with linear and rotary actuators to handle different diameter parts. An old Fanuc robot was integrated into the design and controlled using commands sent from a MicroLogix PLC. A staging and a finished pallet were provided for the robot to pick from and place into after the multi-step process was complete. The additional steps are not shared.

The robot needed to be fenced for safety but operators also needed to be able to access the equipment in multiple areas. The solution was a light curtain routed by mirror around a corner to protect two sides of the machine while allowing for easy maintenance access.

As the sole engineer on the project, I handled every aspect from design, drafting, manufacture/sourcing of components to assembly, wiring, and PLC programming.

The finished machine resulted faster, consistent, and more uniform parts being produced and allowed the operator to focus on other aspects of the manufacturing process. Less operator training was required, allowing for more shifts to successfully operate the machine and increase production.

My name is Jeff Sloop and I am a mechanical engineer with over ten years of experience in design, manufacturing, and automation.

Take the first step towards optimizing your operations – request a quote today and see how we can tailor automation solutions to fit your unique needs.